Product

Test and Measurement

- Test Instruments

- Rheometers & Viscometers

- Pipettes

- Noise & Vibration

- Ultrasonic Thickness Gauge

- Specialized Load Cells

- Data Acquisition

- Signal Conditioner

- General Purpose Digital Measurement Equipment

| SV-A Series | |||||||||||||||||||||||||||||||||||||||||||||||

| Tuning Fork Vibro Viscometers | |||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

| Features | |||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

| Videos | |||||||||||||||||||||||||||||||||||||||||||||||

| External Input / Output | |||||||||||||||||||||||||||||||||||||||||||||||

| RS-232C interface | |||||||||||||||||||||||||||||||||||||||||||||||

| Accessories | |||||||||||||||||||||||||||||||||||||||||||||||

| Click here to see the complete accessory list. | |||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

| Example Measurements with the Tuning Fork Vibro Viscometer (SV/SV-A Series) | |||||||||||||||||||||||||||||||||||||||||||||||

The SV-10/SV-10A series of tuning fork vibro viscometers are capable of continuous measurement over a range of viscosities from the extremely low (0.3 mPa·s) to the high (10,000 mPa·s). These viscometers are able to easily measure the state transition from sol to gel as there is no need to change sensors during measurement. Measurement intervals can be set freely allowing for continuous 24-hour measurement or measurement of any long term viscosity change. |

|||||||||||||||||||||||||||||||||||||||||||||||

Gel point: The liquid to solid phase changeExample) Gelatin, agar, glucomannan, thickening stabilizer, hydrogelCloud point: Micelle structure change in a surfactantExample) Paraffin, non-ionic surfactantsSuspension: A dispersion system such as a slurry, sludge or colloidExample) Cement, butter, milk, cream, asphalt, ink, paint, gold nanocolloidsLubricant Properties: Change in viscosity accompanying temperature changeExample) Engine oil, grease, mineral oil, synthetic oil, water-based lubricants, animal and plant oilsRapid Rise in Viscosity: Measurement of the curing point (measurement of adhesives)Example) Egg white/yolk, solder flux, silicone adhesive, mortar, plaster, rubber and polymer adhesivesLow Viscosity Measurement: Stable measurements around 1.0 mPa·s (viscosity, mouthfeel and sensory tests)Examples) Food related - Water, alcohol, liquors, soft drinks, soy sauce, milk, Medical related - Blood, protein, drugs, easily swallowed foods, easily digested foods Other solvents - cosmetics, semiconductor polishing agentsHigh viscosity measurement: Stable measurements up to 100Pa·sExample) Honey, polymer solutions, toothpaste hand creams, lipstick, chocolate |

|||||||||||||||||||||||||||||||||||||||||||||||

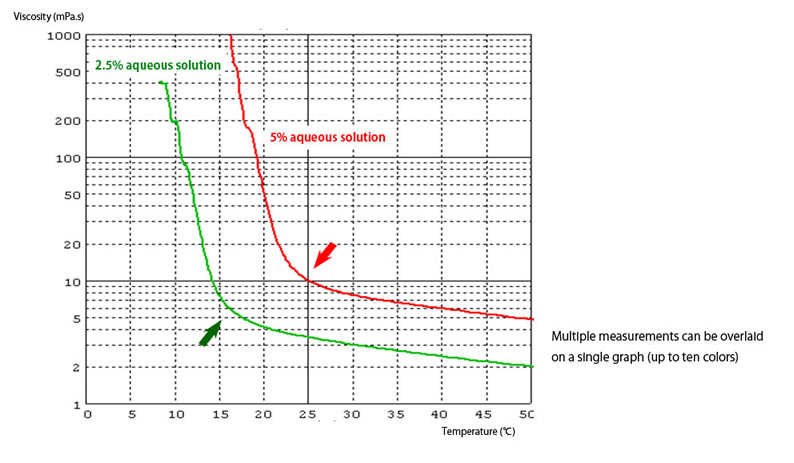

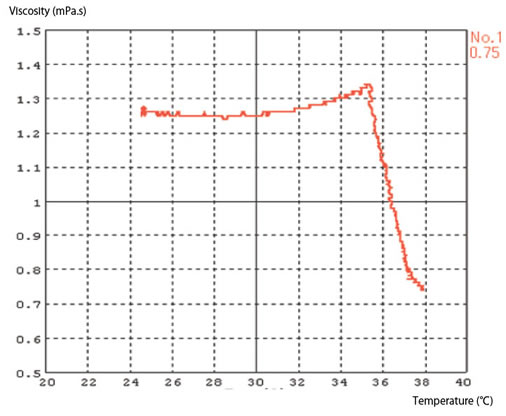

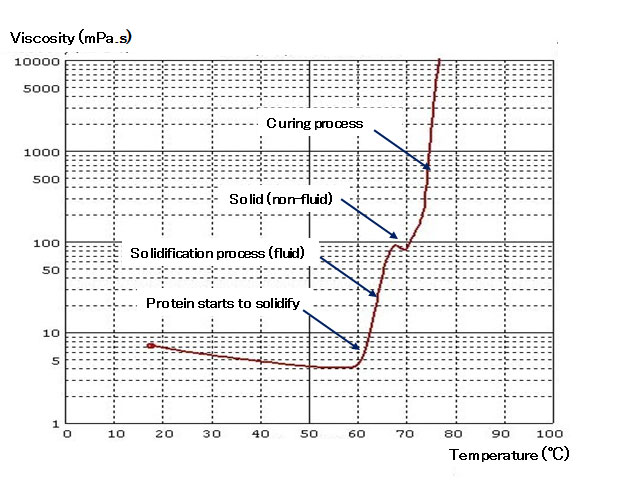

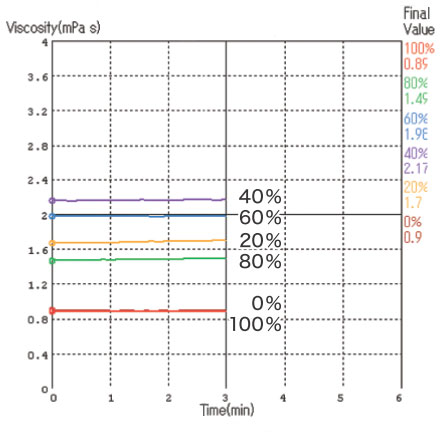

| Gel transition / hydrogel measurement Example) Aqueous gelatin solution This example shows viscosity measurement of 2.5% and 5% aqueous gelatin solutions over varying temperature.  Cloud point measurement Example) Non-ionic surfactant This is the result of a measurement taken while a 1% concentration of a non-ionic surfactant was heated. Surfactants become cloudy when they reach a certain temperature. This is called the cloud point and traditionally could only be measured optically.  Rapid Rise in Viscosity (Measurement of the curing point) Example) Egg whites As egg whites are heated to 60˚C their viscosity will decrease like normal liquids. However, once 60˚ is reached viscosity will increase suddenly, as the proteins in the egg whites clump together.  Measurements at low viscosity Example) Measuring the viscosity of varying concentrations of aqueous ethanol solutions. The viscosity of varying concentrations of aqueous ethanol solutions at 25˚C was measured with the SV-10A. Viscosity of these solutions was shown to vary with concentration. Alone, both 100% ethanol and 100% water have low viscosities but when they are mixed viscosity increases.  |

|||||||||||||||||||||||||||||||||||||||||||||||

| WinCT-Viscosity data processing software | |||||||||||||||||||||||||||||||||||||||||||||||

WinCT-Viscosity is dedicated software that makes realtime graphs of data acquired from the SV Series and SV-A Series viscometers (WinCT-Viscosity supports Windows 8). WinCT-Viscosity allows for simple reading, storage, and analysis of measurement data acquired from SV viscometers. WinCT-Viscosity is comprised of three programs. |

|||||||||||||||||||||||||||||||||||||||||||||||

RsViscoRsVisco allows for realtime graphing of data captured from a viscometer. The changing processes of the observed viscosity and temperature can be displayed simultaneously during measurement. Graphs with differing measurement conditions can be overlaid as well.RsComRsCom transfers data from the viscometer to a computer. It is useful for controlling the viscometer.RsKeyRsKey is used to transfer data taken from a viscometer to other software. |

|||||||||||||||||||||||||||||||||||||||||||||||

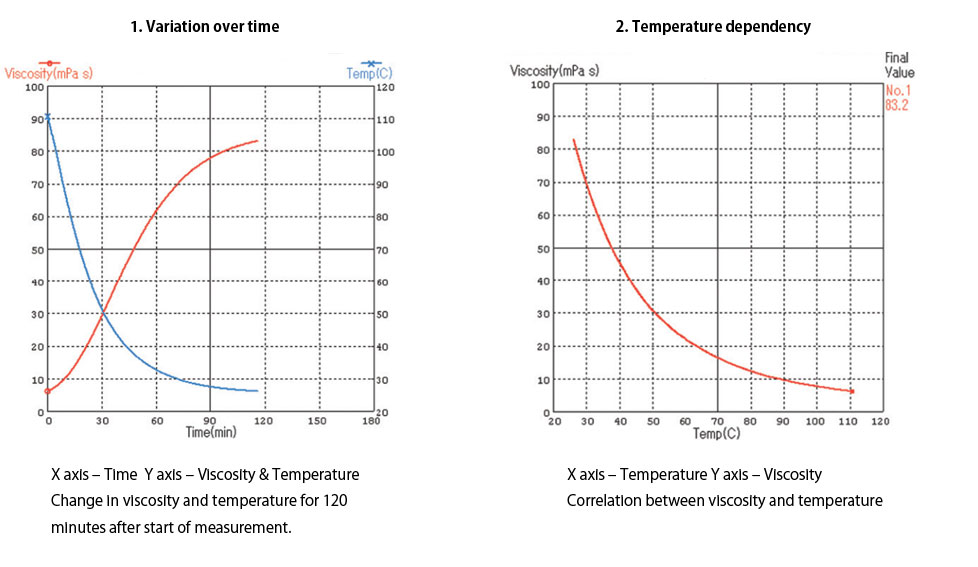

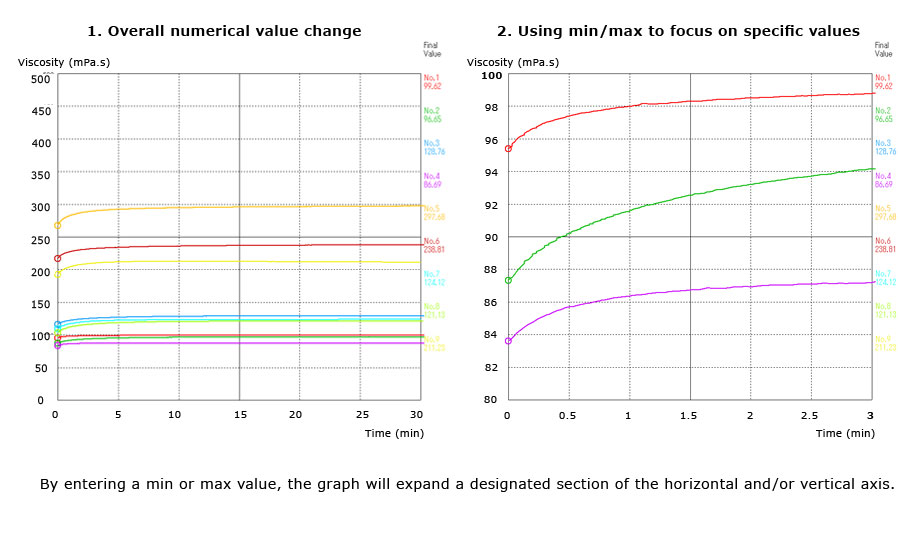

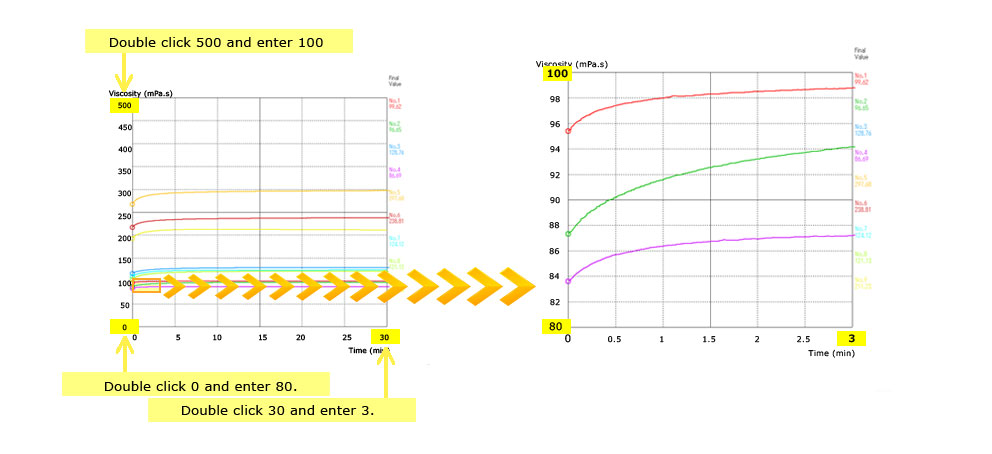

Graphing with WinCT-Viscosity (RsVisco)1. The time axis: Track variation over time Example) Engine Oil 1. Variation over time  Example) Thickening Agent 1. Overall numerical value change  It is possible to expand a designated section of the X and Y axes. Double click to overwrite the value.  |

|||||||||||||||||||||||||||||||||||||||||||||||

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||